Beautiful Plants For Your Interior

Why can aluminum alloy be widely used in high-speed rail car bodies, aircraft wings, and even spacecraft structures? It may seem “thin and light”, but it can bear extremely high strength and support the framework of modern industry. But do you know? The strength of aluminum alloy is not “inborn power”, but stems from five ingenious scientific strengthening methods! From “mixing new friends” for solid solution strengthening, to “forming hard lumps when it rains” for precipitation strengthening, and to “exercising muscles” for deformation strengthening… Each strengthening method is like a series of “defenses” built in the microscopic world, endowing aluminum alloy with excellent mechanical properties and environmental adaptability.

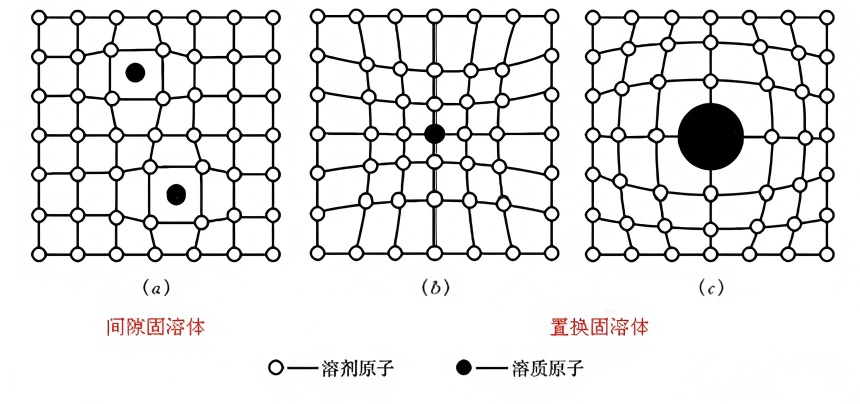

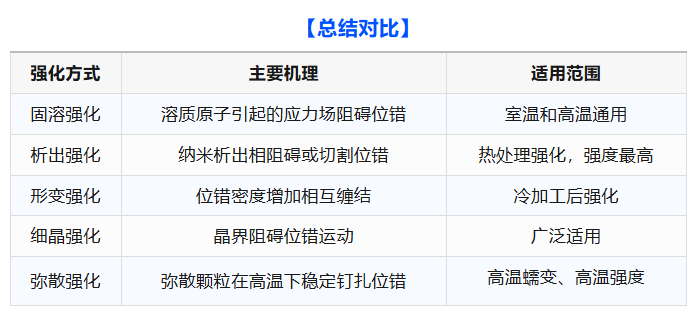

Strengthening method 1: Solid solution strengthening – “Introducing new friends”

Metaphorical illustration: Just like adding salt to water, by dissolving alloy elements (such as Mg, Si, Cu, etc.) into aluminum, a “solid solution” is formed. These elements will hinder the sliding of atoms within the metal, making the aluminum alloy more difficult to be stretched or compressed, and thus becoming harder!

Definition: By introducing one or more alloying elements into the metal matrix, a substitutional or interstitial solid solution is formed. Due to the differences in size, elastic modulus, and electrochemical properties between the solute atoms and the matrix atoms, lattice distortion and stress fields will occur, thereby hindering the movement of dislocations and enhancing the yield strength and hardness of the material.

Main Point:

- Enhancement mechanism: The stress field generated by the solute atoms pinches the dislocations.

- Feature: It has an enhancing effect at both room temperature and high temperatures.

- Representative systems: Al-Mg (5xxx series), Al-Cu (2xxx series)

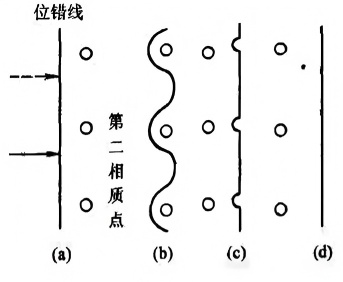

Enhancement method 2: Dissolution enhancement – “Hard lumps formed after the rain”

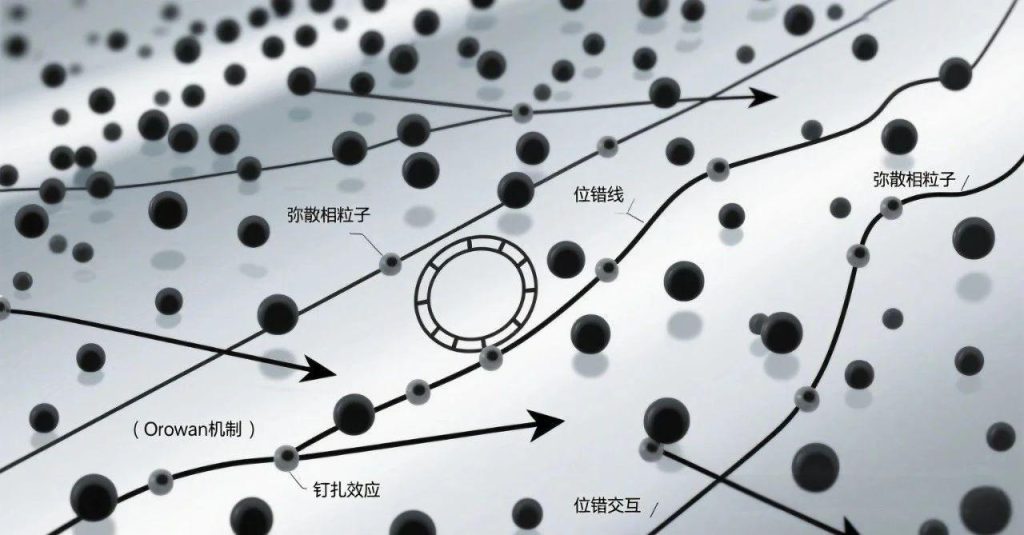

Metaphorical description: During the heat treatment process, aluminum alloys “rain” out nano-sized particles (precipitation phases), which “hard blocks” firmly grip the dislocation movement paths, significantly enhancing the strength.

Definition: Through solid solution treatment followed by rapid quenching, an oversaturated solid solution is obtained. Then, through aging treatment, the solute elements precipitate as precipitate phases. These precipitate phases effectively hinder the movement of dislocations through shear or bypass mechanisms, thereby enhancing the strength.

Main Point:

- Enhancement mechanism: Interaction between precipitated phases and dislocations (Orowan mechanism, cutting mechanism)

- Feature: Heat treatment can be controlled, and the strengthening effect is significant.

- Representative phases: Al-Cu (θ phase), Al-Mg-Si (β” phase), Al-Zn-Mg (η’ phase)

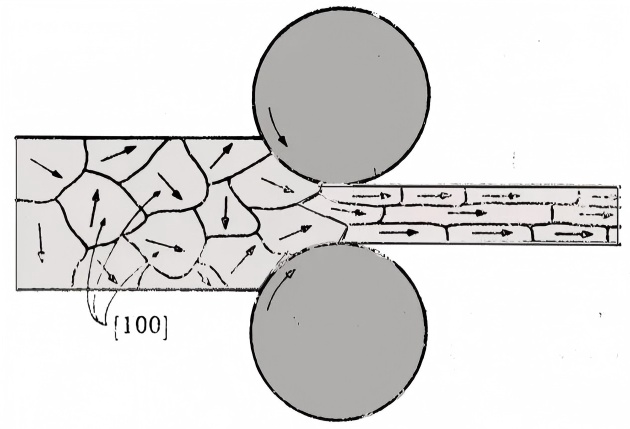

Strengthening method 3: Deformation strengthening – “Building muscles”

Metaphorical illustration: This is similar to fitness training. Through processes such as rolling, stretching, and forging, the internal crystal lattice of the metal undergoes deformation. The numerous small defects can prevent dislocation movement, making the aluminum alloy stronger!

Definition: By introducing a large amount of dislocation density through plastic deformation (such as cold rolling, cold drawing, cold forging, etc.), dislocations come into contact and entangle with each other, hindering movement, thereby enhancing the strength and hardness of the material.

Main Point:

Enhancement mechanism: An increase in dislocation density leads to mutual hindrance among dislocations.

Characteristic: The strengthening effect gradually increases as the deformation amount increases.

Representative state: H state (work hardening state)

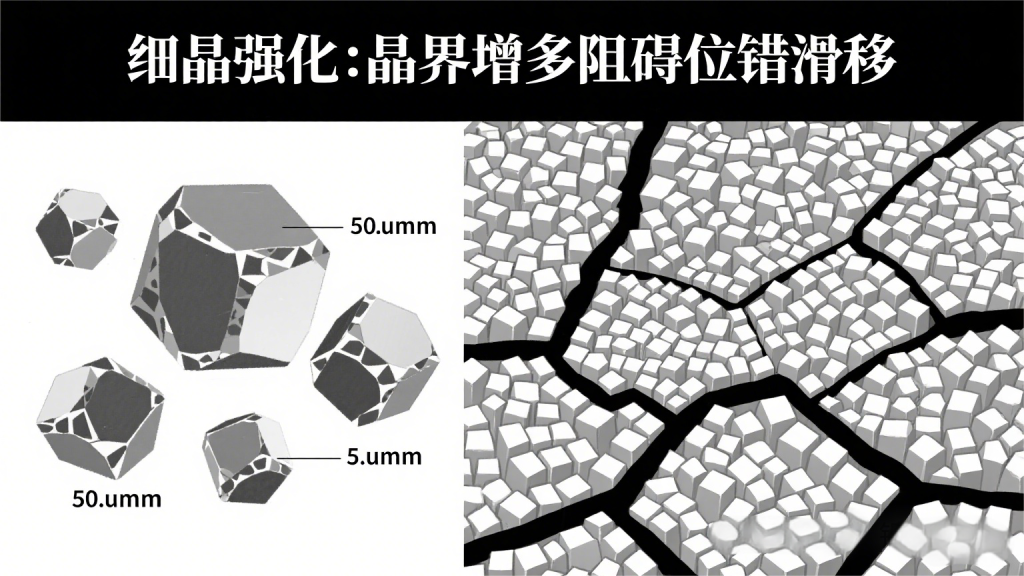

Strengthening method 4: Fine-grain strengthening – “Getting smaller also makes it stronger”

Metaphorical explanation: The smaller the grains are made, the more “grain boundaries” there will be in the metal. These grain boundaries can effectively prevent crack propagation, which is equivalent to building a series of “defensive walls”.

Definition: The grains are refined through plastic deformation, rapid solidification or micro-alloying methods. According to the Hall-Petch relationship, a reduction in grain size and an increase in the number of grain boundaries can significantly enhance the strength of the material.

Main Point:

Enhancement mechanism: Grain boundaries hinder the transmission of dislocations

Feature: Significantly enhances strength while improving toughness

Enhancement method 5: Diffusion enhancement – “Sprinkling nanoparticles”

Metaphorical description: By “dissolving” extremely fine nano-particles (such as Al₃Sc, Al₆Mn, etc.) into the aluminum alloy, these “super obstacles” can firmly hold back dislocations and grain boundaries even at high temperatures, maintaining the structural stability.

Definition: Dispersed within the metal matrix are thermally stable second-phase particles (such as oxides and intermetallic compounds). These particles can continue to play a role in hindering dislocation and grain boundary migration even at high temperatures, effectively enhancing the creep resistance and recrystallization ability.

Main Point:

Enhancement mechanism: The dispersed particles hinder the movement of dislocations and grain boundaries (Orowan mechanism, particle anchoring mechanism)

Feature: Significant improvement in high-temperature performance

Typical examples: Al-Sc alloy (Al₃Sc nanoparticles), Al-Mn alloy (Al₆Mn dispersion phase)

Summary sentence:

The strength of aluminum alloy does not lie in its inherent toughness, but rather in the “scientific proportioning and process strengthening”! Different strengthening methods each have their unique advantages. When combined and customized, an ordinary aluminum material can be transformed into the skin for high-speed rail, the wing beams for aircraft, or even the structural components for spacecraft.

#aluminium alloy #light weight #strengthening mechanism #aluminium profile