Beautiful Plants For Your Interior

In fields such as aerospace, transportation, and building structures, aluminum alloys are widely used due to their excellent properties such as light weight, high strength, and corrosion resistance. But did you know? The strengthening methods for different series of aluminum alloys are completely different! Today, let’s take a look at the strengthening secrets of 1 to 8 series aluminum alloys and see how they are “refined” into materials!

【Detailed Explanation of Enhancement Methods for Each Series】

1xxx series: High-purity aluminum – Basic model, relying on “natural beauty”

- Strengthening mechanism: Primarily relies on work hardening(strain hardening)

- Explanation: Due to the extremely low content of alloying elements, it basically lacks the ability to undergo precipitation strengthening. It has the lowest strength but excellent electrical conductivity.

- Typical applications: cables, conductors, decorative materials, etc.

2xxx series: Al-Cu alloy – Aviation grade, achieved through “aging strengthening”

- Strengthening mechanism: Eutectic strengthening(precipitation strengthening)

- Type of key phases: S phase (Al₂CuMg), θ’ phase (Al₂Cu)

- Explanation: Heat treatment can significantly enhance strength and is suitable for high-strength structural components, but it has relatively poor corrosion resistance.

- Typical applications: aerospace structures, fasteners, automotive components.

3xxx series: Al-Mn alloy – The stable type, relying on “solution strengthening”

- Strengthening mechanism: Solid solution strengthening + Work hardening

- Explanation: Mn forms a dispersed phase which inhibits recrystallization, has good thermal stability, but has moderate strength.

- Typical applications: Roofing materials, cooking utensils, beverage cans.

4xxx series: Al-Si alloy – The durable type – relying on “silicon particles”

- Strengthening mechanism: Solid solution strengthening + Partial alloy precipitation strengthening (such as Mg₂Si)

- Explanation: Si can enhance wear resistance and fluidity. Partial heat treatment can result in moderate strength.

- Typical applications: Engine pistons, welding wires, coating materials.

5xxx series: Al-Mg alloy – Corrosion-resistant type, relying on “solution treatment + work hardening”

- Strengthening mechanism: Solid solution strengthening + Work hardening

- Explanation: The higher the Mg content, the greater the strength; it has good corrosion resistance, but when the Mg content exceeds 3%, stress corrosion is prone to occur.

- Typical applications: Shipbuilding, transportation, pressure vessels.

6xxx series: Al-Mg-Si alloy – All-round performer, relying on “aging strengthening”

- Strengthening mechanism: Exsolution strengthening (dominated by the β” phase)

- Key phase types: β → β′ → β(Mg₂Si)

- Description: The mechanical properties and formability are well balanced. The properties can be regulated through heat treatment, and it is suitable for various structural components.

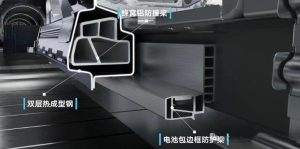

- Typical applications: architectural profiles, bicycle frames, vehicle body panels.

7xxx series: Al-Zn-Mg(-Cu) alloy – The Elite, relying on “super strong aging”

- Strengthening mechanism: Eutectic strengthening (η’ phase: MgZn₂)

- Description: This is the strongest type of aluminum alloy, widely used in high-performance structures, but its formability and corrosion resistance need to be controlled.

- Typical applications: aircraft structures, sports equipment, high-speed trains.

8xxx series: Special aluminum alloy – The cutting-edge tech style, relying on “function enhancement”

- Strengthening mechanism: Due to the complexity of the series, the strengthening methods are diverse, usually including work hardening or solid solution strengthening.

- Description: Suitable for special functional applications, such as aluminum foil, battery casings, and packaging materials.