Beautiful Plants For Your Interior

Episode 11: Comprehensive Comparison of Aluminum Alloy Materials at Home and Abroad – Various Typical Applications of Aluminum Alloy Grades

Beautiful Plants For Your Interior

The aluminum alloy codes are based on the AA standard of the American Aluminum Company and are represented by four digits to denote various different alloys. 1xxx: Pure Aluminum 2xxx: Al-Gu alloy 3xxx: Al-Mn alloy 4xxx: Al-Si alloy 5xxx: Al-Mg…

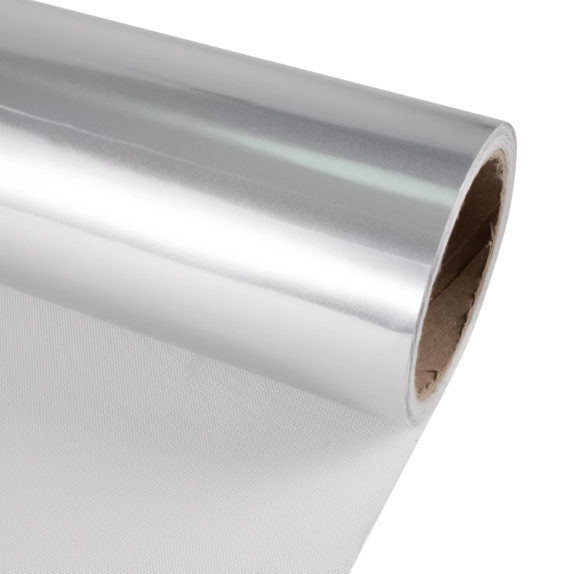

8st series aluminum The more commonly used one is 8011, which belongs to another series. It is an aluminum plate mainly used for making bottle caps and is also applied in radiators. Most of the applications are aluminum foils. It…

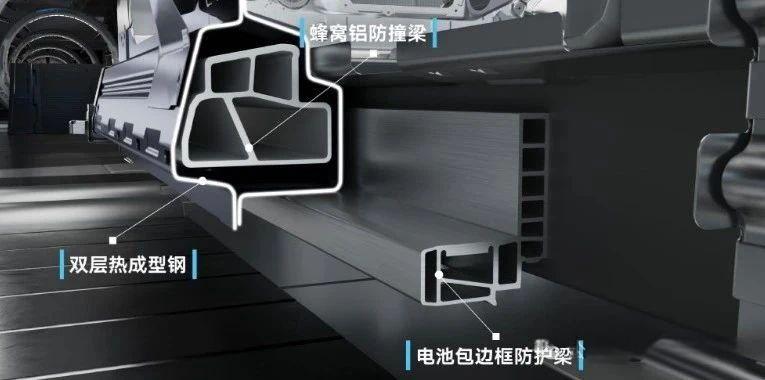

7st series aluminum ①7000 series aluminum alloy is another commonly used alloy, with a wide variety of types. It contains zinc and magnesium. Among the common aluminum alloys, the one with the best strength is 7075 alloy, but it cannot…

6st series aluminum The main alloying elements of the 6XXX series alloys are magnesium and silicon (AlMgSi1Cu), and a Mg2Si phase is formed. If a certain amount of manganese and chromium are present, they can neutralize the negative effects of…

5st series aluminum ①The 5XXX series is a high-magnesium alloy (5A06 (LF6) and 5A05 (LF5), which has excellent strength and corrosion resistance, as well as good machinability in non-heat-treatable alloys. The surface becomes aesthetically pleasing after anodizing treatment. The arc…

4st series aluminum The 4xxx series of aluminum rods are represented by 4A01. The 4000 series of aluminum plates belong to the series with a higher silicon content. Usually, the silicon content is between 4.5% and 6.0%. They are used…

3st series aluminum The 3XXX series is an AL-Mn alloy, which is the most widely used type of anti-rust aluminum. This alloy has relatively low strength (slightly higher than industrial pure aluminum) and cannot be strengthened through heat treatment. Therefore,…

2st series aluminum The 2XXX series is a typical hard aluminum alloy in the aluminum-copper-magnesium system. Its composition is relatively reasonable and its comprehensive performance is good. This alloy is produced in many countries and is the most widely used…

1st series pure aluminum The 1XXX series is formed by adding a small amount of copper elements to pure aluminum. It possesses excellent forming processing characteristics, high corrosion resistance, good weldability and conductivity. The 1XXX series aluminum alloy is widely…

Aluminum material properties, classification of aluminum alloy grades There are over 1,000 registered aluminum alloy grades internationally, and each grade has multiple states. There are significant differences in hardness, strength, corrosion resistance, machinability, weldability, and decorative properties among them. When…

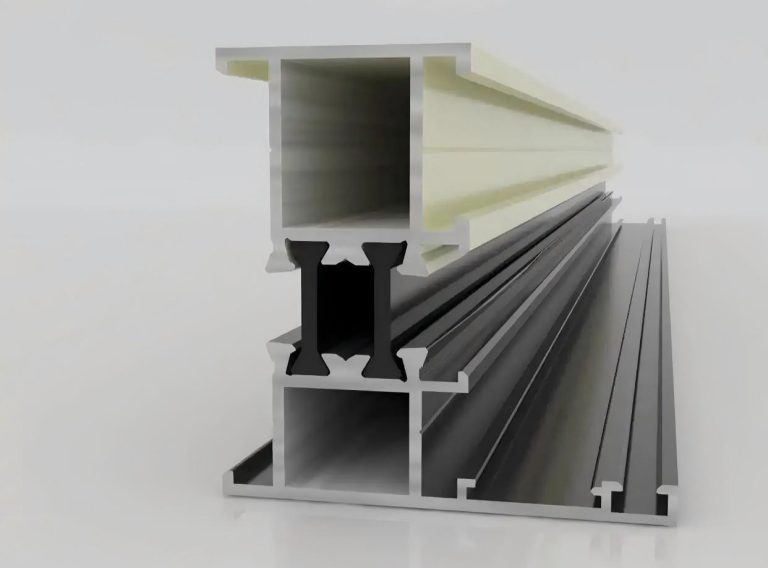

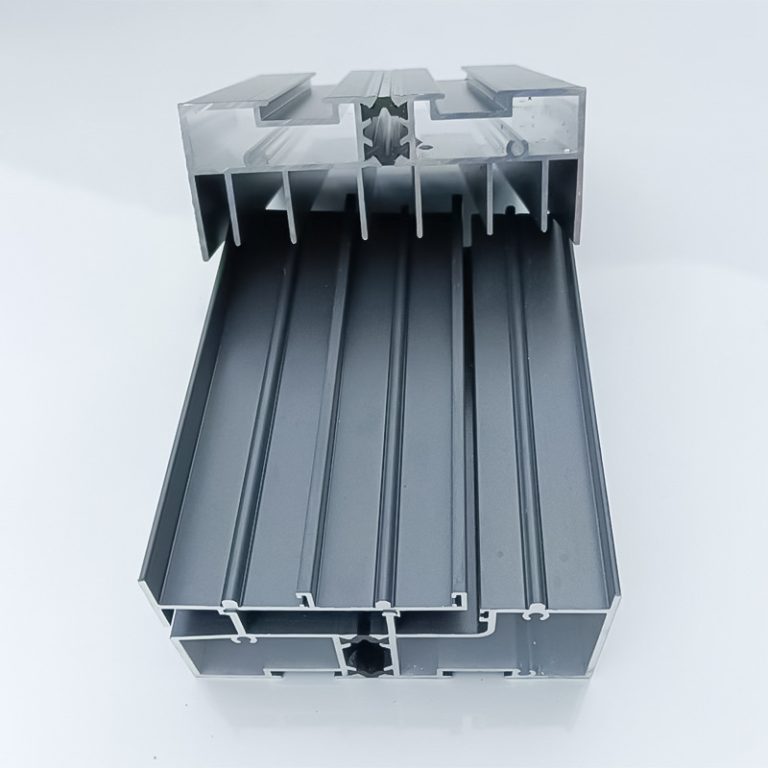

Aluminum alloy profiles are widely used in the construction industry due to their environmental friendliness, stability, ease of processing and decorative properties. Aluminum alloy profiles can be classified into base profiles, anodized profiles, electro-coated profiles, powder-coated profiles, fluorocarbon-coated profiles, through-bar…

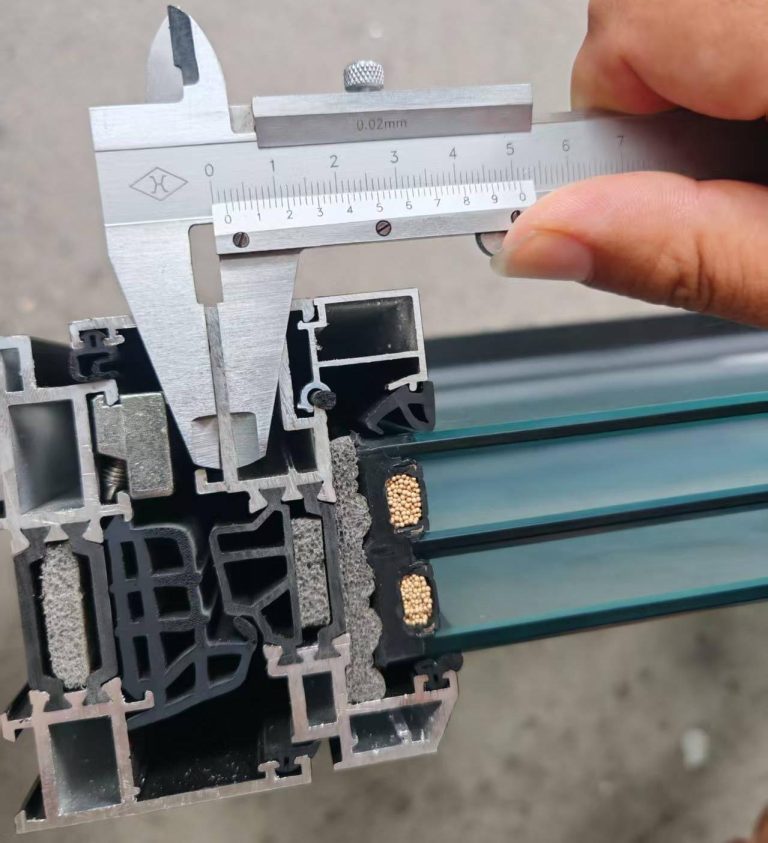

The production of aluminium alloy doors and windows has passed a series of strict tests and can only be delivered after meeting the specified performance indicators. So, what are the main properties of aluminium alloy doors and windows? Sealing Design…

The surface treatment of aluminum alloy involves creating a layer with certain or multiple special properties on the surface of the material through physical or chemical methods. Through this surface treatment, the performance of the product in terms of appearance,…

In residential aluminum alloy doors and windows, the frame and sash materials commonly used are 6063-T5 profiles. These profiles possess excellent processing performance, extrusion properties and electroplating capabilities, along with good corrosion resistance, flexibility and outstanding anti-oxidation effects. Their hardness…

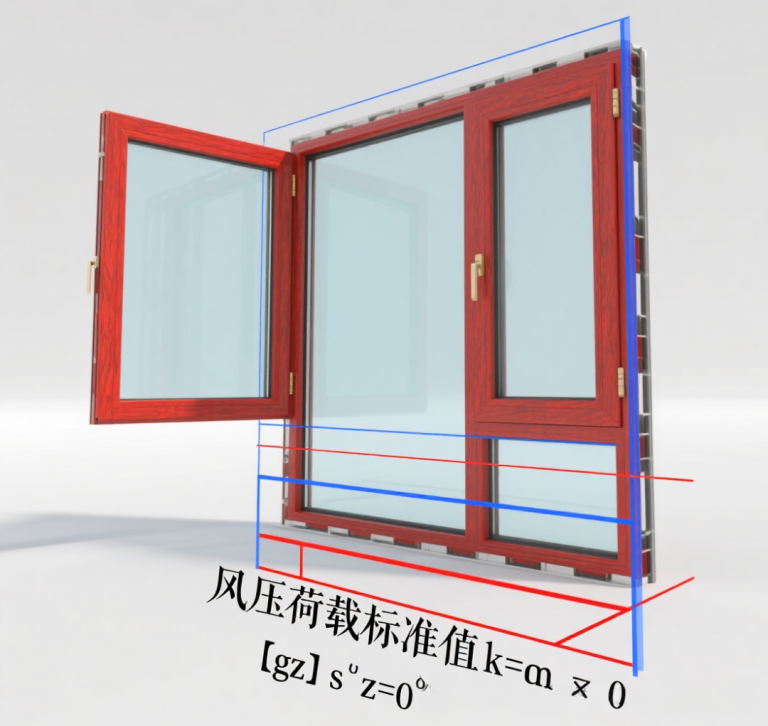

During the process of choosing doors and windows, apart from the selection of material types (such as common aluminum alloy and thermal break aluminum), material brands, and opening methods (such as casement and sliding), many consumers are confused by the…

What are the characteristics of aluminum alloy doors and windows? Advantages of Dianqiao aluminum alloy doors and windows: resistant to corrosion, good weather resistance, free of harmful substances such as formaldehyde, superior insulation and heat preservation performance, in line with…

Installation process of sliding doors and windows Frame and sash cutting → Frame and sash milling opening → Mill lock hole groove → Drill hardware hole → Cut glass trim → Install frame and sash sealing strips → Install glass…

The grade and status code of aluminum alloy door and window profiles are their important identity markers, directly reflecting the basic chemical composition, mechanical properties and processing technology of the material. Understanding these codes is crucial for correct material selection,…

Windows and doors are usually classified by material into: wooden windows, steel windows, plastic-steel windows, aluminum alloy windows, thermal break aluminum alloy windows, polyurethane windows, aluminum-clad wood, and wood-clad aluminum windows, etc. We will briefly describe the profiles, glass, hardware,…

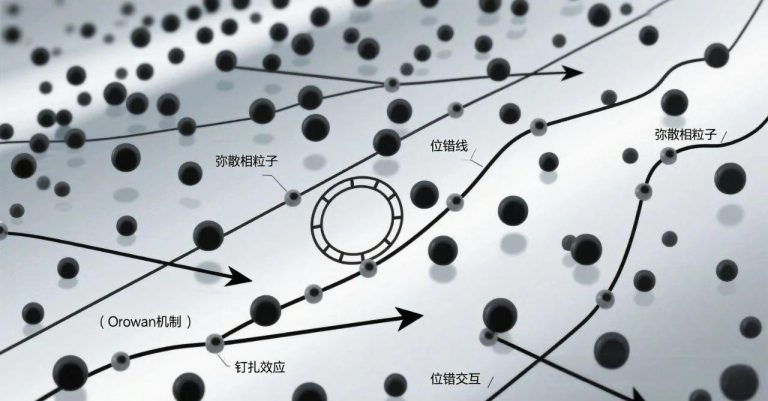

Why can aluminum alloy be widely used in high-speed rail car bodies, aircraft wings, and even spacecraft structures? It may seem “thin and light”, but it can bear extremely high strength and support the framework of modern industry. But do…

In fields such as aerospace, transportation, and building structures, aluminum alloys are widely used due to their excellent properties such as light weight, high strength, and corrosion resistance. But did you know? The strengthening methods for different series of aluminum…

Aluminum alloy extrusion principle Utilizing the plastic deformation property of metals: Place the aluminum alloy billet that has been heated to a softened state (usually at 350-500℃) into the barrel of the extruder. Through extrusion, the billet is forced to…

Aluminum profiles are very common building materials in high-end decoration, curtain walls and gardens. Construction professionals must understand the basic knowledge of aluminum profiles. Today, we will explain them one by one from the following five aspects. The factors influencing…

Nitriding of complex-shaped extrusion dies may lead to uneven nitriding layers, with certain areas in the working band region possibly failing to achieve the required hardness. The sample dies were gas nitrided under controlled nitriding potential. A two-stage gas nitriding…

There are hundreds of variables in today’s extrusion plants. This starts with the selection of the billet, and during the casting process, it has its own set of variables, beginning with the chemical composition. For example, the 6005A alloy is…

The latest data from the National Bureau of Statistics shows that the aluminum industry chain in China maintained a stable development trend in the first half of 2025. From January to June, the cumulative output of aluminum products across the…

The mechanical calculation of system window installation mainly focuses on core indicators such as wind pressure resistance, load-bearing capacity, and connection strength to ensure stability and safety in the usage environment. Essentially, it uses scientific formulas and models to verify…

Anodized aluminum is aluminum that has undergone anodizing treatment. Its surface is very durable, corrosion-resistant and aesthetically pleasing. This process involves electrochemical treatment in a series of baths to form an anodic layer directly on the aluminum surface. This layer…

The Aluminum Association has released a new report, titled “Building the Future: Trends in Aluminum Use in the U.S. Construction Market,” authored by Ducker Carlisle. The report concludes that aluminum usage in the construction and building market could increase by…

The US aluminium industry has been continuously developing over the past 25 years and has transformed its business into a global powerhouse in midstream and downstream aluminium production and recycling – having invested over 10 billion US dollars in its…

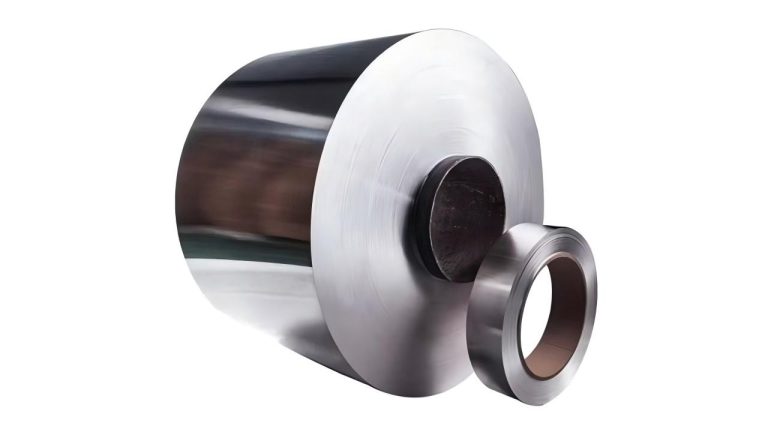

1、Definition: Depending on the processing technology, aluminum processing products can be divided into two major categories: one is aluminum profiles produced by the casting-extrusion process; the other is aluminum sheets, strips and foils produced by the hot rolling-cold rolling process.…

As of mid-July 2025, the global aluminum profile industry faces a mix of challenges from trade policies and seasonal demand fluctuations. The U.S. announced plans to impose a 30% tariff on aluminum products imported from Mexico and the EU starting…

As a leading exporter of premium aluminum alloy profiles, we take pride in delivering products that redefine industry standards. Our aluminum solutions combine cutting-edge technology with time-tested durability, making them the ideal choice for global partners across construction, automotive, aerospace,…

Industry Dynamics: Industrial Aluminum Profiles Surpass Construction Sector in Demand ShareIn the first half of 2025, China’s aluminum profile industry showed a differentiated trend of “adjustment in traditional sectors and explosive growth in emerging tracks.” According to data from the…

We have been deeply involved in the aluminum products industry for many years,always playing the role of a “bridge” to provide customers with a more reliable value network. We do not produce aluminum materials, but adhering to the principle of professionalism,we…