Beautiful Plants For Your Interior

Aluminum profiles are very common building materials in high-end decoration, curtain walls and gardens. Construction professionals must understand the basic knowledge of aluminum profiles. Today, we will explain them one by one from the following five aspects. The factors influencing the price will be elaborated in detail at the end.

What is aluminium profile?

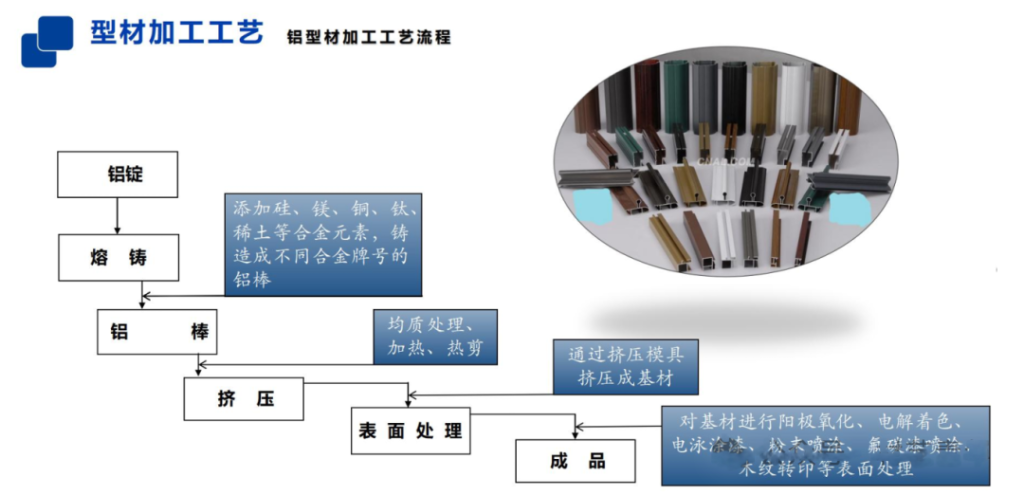

- Aluminum profiles are obtained by melting and extruding aluminum rods, resulting in aluminum pipe materials with various cross-sectional shapes.

What is an aluminum rod?

- Aluminum rods are a type of aluminum product. Aluminum ingots are alloys formed through processes such as melting, purification, removing impurities, eliminating gases, removing residues, and adding other metal substances during the casting process.

What is an aluminum ingot?

- The pure aluminium produced by electrolysis from aluminium ore, according to the national standard (GB/T 1196 2008), should be called “aluminium ingot for remelting”, but people have come to call it “aluminium ingot” instead. Some people call the “A00” aluminium, which actually has an aluminium purity of 99.7%, “standard aluminium”, and it is called “standard aluminium” in the London market.

A、Classified by the application of aluminum profiles:

1、Building aluminum profiles (divided into doors and windows as well as curtain walls)

2、Aluminum profile for radiator.

3、Industrial aluminum profiles: Primarily used in industrial production and manufacturing, such as automated machinery equipment, sealing frame structures, and each company customizes mold design according to their own mechanical equipment requirements, such as conveyor belts for assembly lines, elevators, dispensing machines, inspection equipment, shelves, etc. They are mostly used in the electronic machinery industry and clean rooms.

4、Aluminum alloy profiles for rail vehicle structures: Mainly used for the manufacturing of the body of rail vehicles.

5、Frame aluminum profiles to make aluminum picture frames, and use them to frame various exhibition and decorative paintings.

B、Classified by alloy type and condition:

1、Non-heat-treated alloys: Pure aluminum – 1000 series, aluminum-manganese alloy – 3000 series, aluminum-silicon alloy – 4000 series, aluminum-magnesium alloy – 5000 series.

2、Heat treatment alloys: Aluminum-copper-magnesium alloy – 2000 series, Aluminum-magnesium-silicon alloy – 6000 series, Aluminum-zinc-magnesium alloy – 7000 series

3、Heat treatment code:

T1 – Artificial aging

T2 – Annealing

T4 – Solution treatment with natural aging

T5 – Solution treatment followed by incomplete artificial aging

T6 – Solution treatment followed by complete artificial aging

T7 – Solution treatment followed by stabilization treatment

For example: The three most commonly used aluminum alloy materials in curtain wall projects are: 6063-T5, 6063-T6, and 6061-T6.

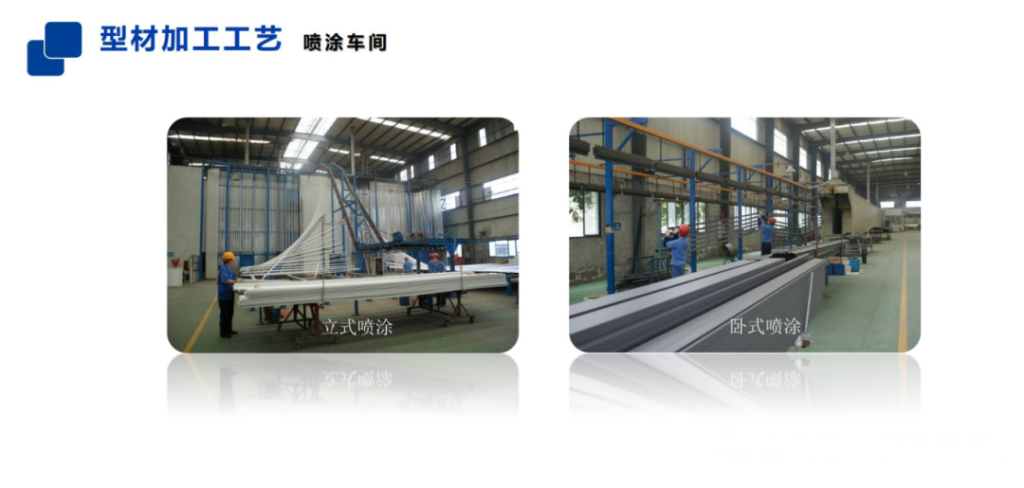

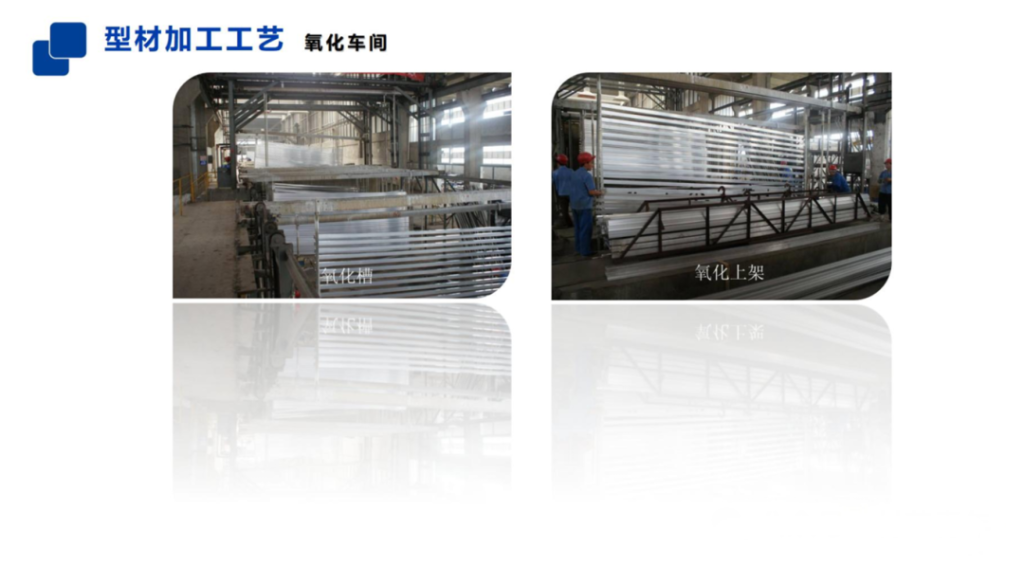

C、Classified by the surface treatment methods of aluminum alloys:

- Anodic oxidized aluminum

- Electrostatic coating aluminum

- Powder coating aluminum

- Wood grain transfer printing aluminum

- Fluorocarbon coating aluminum

- Polished aluminum (divided into mechanical polishing and chemical polishing; among them, chemical polishing has the highest cost and is the most expensive)

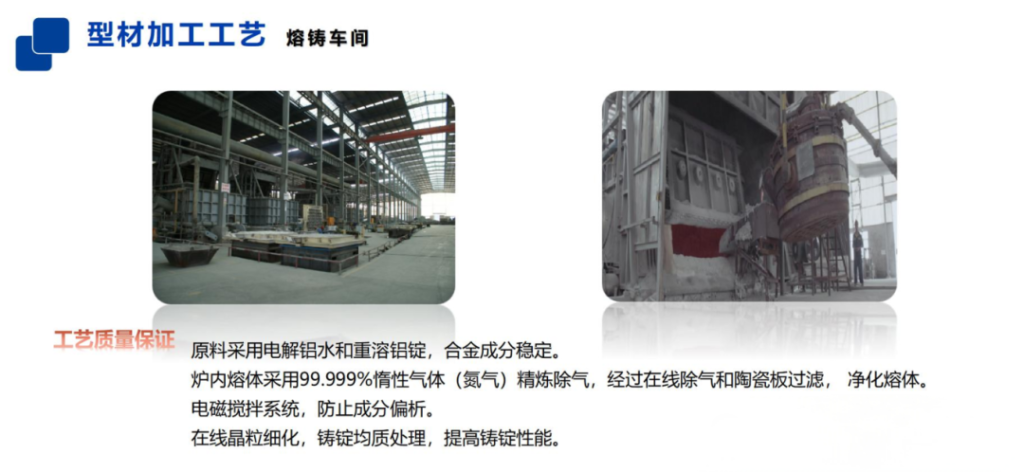

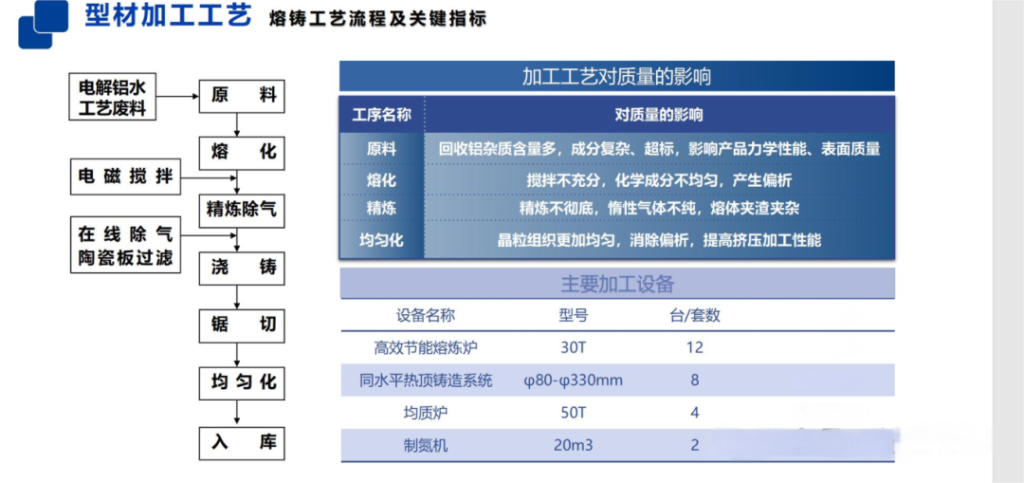

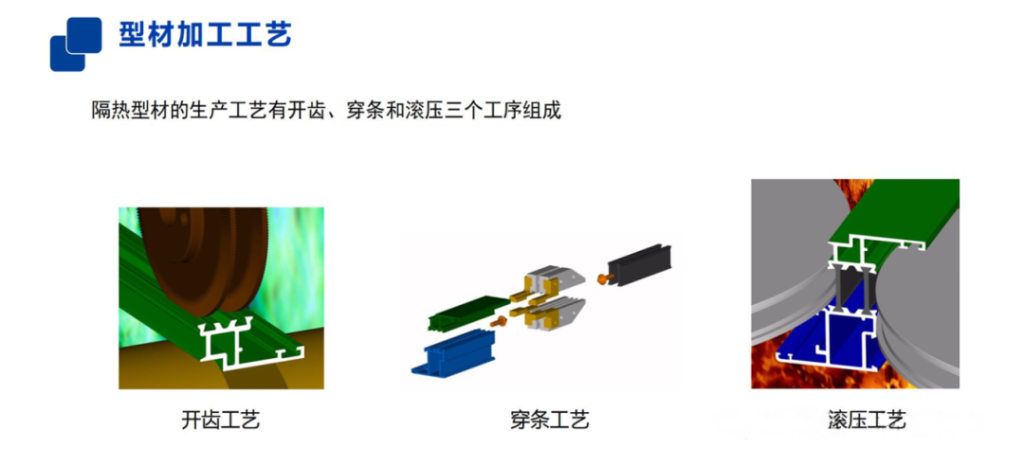

Aluminum profile processing technology

- Process Description: Quenching

The purpose of (cooling) is to “freeze” the alloy elements, namely magnesium and others, to stabilize the unstable magnesium and silicon atoms and prevent them from settling down, thus maintaining the strength of the profile. The three main quenching methods include: air cooling, water mist cooling, and water tank cooling. Which quenching method to use depends on the extrusion speed, the thickness of the profile, and the required physical properties, especially the requirement for strength. Aging refers to the fact that most profiles need to undergo heat treatment in an aging furnace after quenching. The main effect of aging is to reconfigure the alloy elements (magnesium and silicon) so that they can be evenly distributed throughout the profile, thereby increasing the strength of the profile. Temperature and time are two indicators that must be strictly controlled in artificial aging. In the artificial aging furnace, the temperature at each part must be the same.

Cost composition of aluminum profiles

The pricing method for aluminum profiles is as follows: for anodized, anodized electro-etching coating, and powder electrostatic spraying, it is calculated based on the futures price of aluminum ingots plus processing fee (yuan/ton); for fluorocarbon coating, the pricing method is the futures price of aluminum ingots plus material processing fee (yuan/ton) plus fluorocarbon spraying area (yuan/square meter). Generally, the processing fee for aluminum profiles has an ex-factory price (including taxes), which does not include transportation cost. Then, depending on the distance of transportation, a corresponding transportation cost (yuan/ton) is added to the original ex-factory price. Therefore, transportation cost is an important factor that must be considered in the negotiation process of aluminum profiles.

The material and price of aluminum profiles

The common aluminum profiles used for curtain walls are 6063-T5, 6063-T6, and 6061-T6. Among them, T6 has a slightly higher strength than T5. The difference in processing between T5 and T6 lies in that the former uses air cooling during the cooling process of the aluminum material, while the latter uses water cooling, which incurs water costs. However, for our material procurement, since the usage of T6 in projects is generally not large, the manufacturers often do not charge extra fees for T6 in order to secure the bid. The industry standard charge is that T6 is charged an additional processing fee of 200-300 yuan per ton on top of the T5 unit price. The usage of 6061 profiles is not too much, and they are mainly used for pads, blocks, safety clips, and limit blocks, etc. Their mechanical properties and corrosion resistance are significantly higher than those of 6063 aluminum profiles. The industry charge is generally an additional 800-1000 yuan per ton on top of the 6063 unit price.

The weighing method for aluminum profiles

The weighing methods for general profiles are divided into weighing on the scale and theoretical weighing. The so-called weighing on the scale refers to the total weight of the profile, the weight of the packaging paper, and the weight of the surface coating material. Generally, the weight of the packaging paper for each ton of profile is between 40 and 60 kg, while the weight of the powder coating for each ton of profile is 40 kg. Calculated based on the purchase price of 21 yuan per kg, the additional costs for each ton are 840 – 1260 yuan and 840 yuan respectively. Additionally, during the extrusion process of the profiles, the inner surface of the mold will expand due to continuous extrusion, causing an increase in the wall thickness of the profile and resulting in unnecessary cost waste. For suppliers, this not only saves the cost of replacing substandard molds but also expands the contract share and increases the profit margin. Therefore, in the purchase of aluminum profiles, we should advocate theoretical weighing. If theoretical weighing is adopted, in the negotiation, it is necessary to first agree on the theoretical weighing method, which is calculated by multiplying the cross-sectional area of the mold by the length to calculate the volume, and the density is executed at 2.70 tons per cubic meter. If the density is not agreed upon in the negotiation, some manufacturers may claim to weigh based on 2.71 tons per cubic meter – 2.73 tons per cubic meter.

Fixed-length processing

In project management, to reduce material waste or to meet structural requirements, the lengths of profiles usually need to be processed to specific dimensions. However, generally, the production lengths of aluminum profiles by manufacturers are within 6 meters as the standard size. But in project management, to reduce material waste or to meet structural requirements, the lengths of profiles usually need to be processed to specific dimensions. In actual design, there will be profiles longer than 6 meters, and there will also be profiles with lengths less than 6 meters. Therefore, during price negotiations, it is necessary to anticipate and propose in advance. Generally, profile manufacturers will not increase the price for this reason. When calculating transportation costs, manufacturers usually calculate based on the standard size. If the profile length exceeds 6 meters, such as 9 meters, the manufacturer will require the use of a 13-meter truck for transportation, and the low utilization rate of the truck will result in the procurement party having to bear this cost. Therefore, during negotiations, it is necessary to clearly define the transportation cost terms to avoid the risk of price increases during the performance of the contract.

Aluminum profile mold fees and refund standards

In the past years of the curtain wall projects, the number of aluminum profiles for mold production was usually very small and the molds were not very large. Therefore, the cost of molds accounted for a relatively small proportion in the total contract. Some manufacturers even offered the discount of free mold fees. However, in the recent large-scale curtain wall projects, the number of molds involved was large (basically new molds needed to be developed), and the diameters of the molds were also getting larger (many with an outer truncated circular diameter exceeding 200mm), and the mold costs often reached hundreds of thousands of yuan. Therefore, the mold production costs of manufacturers have also been increasing, and the mold return standards have become increasingly strict. It is almost impossible for those domestic first-class brand manufacturers to be exempted from mold fees. But during the negotiations with them, we have basically understood their mold pricing model and formulated a relatively favorable mold negotiation plan. For projects with a small amount of profile usage, usually during the negotiation, the mold discount and corresponding refund standards need to be agreed upon to strive for the most lenient conditions; for projects with a large consumption of profiles (over 700 tons), in the strategy formulation for negotiations, we try to require the manufacturers to provide free molds with an outer truncated circular diameter of <250mm, and for molds with an outer truncated circular diameter of ≥250mm, charge according to the manufacturer’s mold discount rate of 5-8% (no refund). In addition, during the bidding process, we try to make the suppliers quote for molds as well, because the pricing of molds by different manufacturers varies, among the several first-class brands, the mold fee of Asia Aluminum is the highest, and the mold fee for the same diameter is almost doubled compared to other manufacturers.

The agreement regarding the reference price of aluminum ingots

The price of aluminum ingots is an important component of the price of aluminum profiles. Generally, the average spot price of aluminum ingots on the internet on the day of placing the order is referred to. The two main web pages mainly referred to are Shanghai Changjiang Nonferrous Metals Network and Nanhai Lingtong Nonferrous Metals Network. However, the price of aluminum ingots on the former is lower, while that on the latter is higher. The quotations of the two generally differ by 250 yuan per ton. As a manufacturer, they will definitely prefer to choose the Nanhai Lingtong Nonferrous Metals Network. But during the actual negotiation process, especially for manufacturers in the central or northern regions, they can accept the futures price of aluminum ingots on the Shanghai Changjiang Nonferrous Metals Network. While for manufacturers in the south, they usually accept the price on the Nanhai Lingtong Nonferrous Metals Network. Therefore, during the negotiation, one should consciously strive to secure the unit price of aluminum ingots on the Shanghai Changjiang Nonferrous Metals Network as the settlement basis.