Beautiful Plants For Your Interior

There are hundreds of variables in today’s extrusion plants. This starts with the selection of the billet, and during the casting process, it has its own set of variables, beginning with the chemical composition. For example, the 6005A alloy is composed of aluminum and eight main elements, including Si, Fe, Cu, Mn, Mg, Cr, Zn, and Ti, as well as a small amount of other elements. Other variables in the aluminum rod production process include waste loading, melting, impurity removal, grain refinement, degassing, and processing speed, all the way to solidification, thermal cracking, mold temperature control, lubricants, homogenization, stress relief, sawing, and handling. Since most extrusion machines do not produce aluminum rods internally, or even not in the same manufacturing plant, it can be decided whether the machine learning model should include details of aluminum rod production, or only the alloy composition of the received billets.

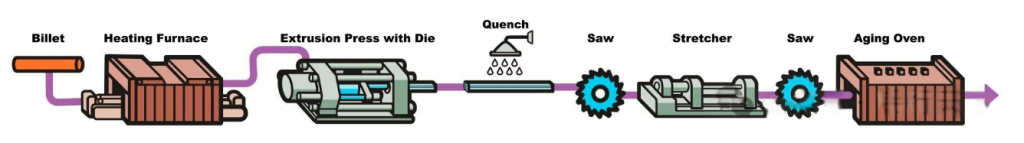

Illustration: The typical process of the extrusion workshop begins with the selection of high-quality raw materials, and continues through aging and the final processes.

During the extrusion operation itself, the billet is cut to a certain length and loaded into the heating furnace, then into the extrusion machine. The extrusion shape is immediately subjected to quenching treatment, and then subjected to stretching, sawing and aging treatment according to customer requirements. Each step in the extrusion process represents an increasing number of variables that need to be considered. In the aluminum rod heating furnace, the main variables include the diameter and length of the aluminum rod, alloy, speed, starting temperature, taper (gradient), heating efficiency and energy consumption.

The three most important variables in extrusion are “temperature, temperature and temperature”. Once the preheated aluminum rod enters the extruder, the variables include velocity and force (pressure), as well as the flow of the metal through the mold.

Engineers and metallurgists also focus on the microstructure, strain rate and mechanical properties achieved by specific alloys and geometric shapes under optimized processing conditions. Higher billet heating temperatures help to increase the ultimate tensile strength (UTS) and yield strength (YS) of longitudinal welds, while the influence of extrusion speed is minimal. However, to maximize throughput, extrusion speed is crucial, and this is where a balance is struck between quality, performance and speed.

The extrusion die has its own complexity, ranging from geometric shape to heat management, wear, mold life, and performance differences between different molds. After extrusion, the profiles are immediately quenched when they leave the press. The hot extrusion is blown with air and/or water at a specified rate to cool the profiles. Quenching is crucial for successfully developing geometric straightness and meeting the required mechanical properties. The contour geometry and wall thickness have a significant impact on the quenching efficiency. Thick walls are difficult to cool, while internal depressions are difficult to reach through water spraying. The extrusion production line speed can be adjusted according to the requirements of the profiles, wall thickness, microstructure, and mechanical properties. The quenching equipment is designed to meet these requirements while maximizing quality and extrusion speed.

The variables during the quenching process include inlet and outlet temperatures, water temperature, water pressure, as well as extrusion dimensions, shapes and wall thickness indicators. Johnny Pangborn from Metal Star Consulting pointed out other variables in the quenching tank, including nozzle design (conical, elliptical or flat spray) and direction (0 – 45°). The quenching system itself can ensure its own machine learning model, as many industry experts refer to it as a “black box”, and there is very little information available from the quenching system itself. This makes it even more important to measure and analyze quenching data to eliminate mystery.

After the quenching tank, there is usually a sensor to measure the final temperature of the profile – representing another variable. However, for this sensor, there is concern that the reflective surface of the aluminum might affect the measurement accuracy. To solve this problem, some high-temperature meters include an emissivity enhancer. When combined with the ability to program the camera to adjust the reflectivity of the aluminum, more accurate readings can be obtained.

The puller transports the profiles to the oscillation table, and then cuts the profiles using the fly-cutting system or other saws. Then the contour is moved to the cold bed. According to Pangborn, mechanical stretching causes the material to undergo strain, increases dislocations, thereby improving straightness and mechanical properties. During the stretching process, force and speed may have the greatest impact and are designated as input variables in the AI model.

Then, the extruded parts are further processed through precision cutting and sawing, which cuts them to the desired lengths. The consistency and quality of the cutting are crucial for meeting the customer’s requirements. After cutting, according to the mechanical performance requirements, the profiles are sent to the holding pressure zone or the heat treatment zone. T6 tempering is quite common and requires specific heat treatment formulas. The extruder usually re-examines the product requirements to determine if the heat treatment can be reduced, as the processing time brings financial and productivity burdens.

Overall productivity encompasses many other variables, including inputs (data input into the AI model) and outputs (also known as measurable results). Downtime is certainly an important input. This situation occurs in various ways, such as dead loops (i.e., the time period between two printing runs). During dead loops, various activities take place, such as cutting off waste material (the tail of the billet or the waste end of the profile) after extrusion, inserting new billets or workpieces into the press, and performing hiccup cycles (the process of removing any trapped air in the billet). Additionally, downtime may include any tool changes, mechanical maintenance, or other activities that require a pause in the pressing operation. Therefore, reducing dead loop time can significantly improve overall productivity.

The stretching operation may search for various outputs from its data model. Typical outputs include the parameters requested by the customer, such as yield strength, ultimate tensile strength, elongation rate, VDA (three-point bending test), dimensions, straightness and aesthetics (without scratches or marks). Other outputs may include operational or management indicators that drive business outcomes, including waste, waste costs and energy efficiency.

Model

Once the extruder has determined which data is needed, these variables need to be organized into a table in the spreadsheet to build a structured dataset for AI analysis. The alloy composition and processing variables will be the input, while mechanical properties, quality, and throughput indicators will be the output.

Building a strong dataset not only helps in solving the output variables, but also offers other advantages. Sometimes, opportunities arise to receive requests from customers or potential customers, which exceed the standard limits of elongation or strength. By leveraging robust algorithm models, the elongation can be set at the target level, and then the model can be reversed to solve for the input values (process indicators or alloys) required to achieve the desired mechanical performance level.

AI appears in the news almost every day. Some of these news are good news, while others are bad news. When it is tailored for large-scale, factory-shutdown production, many of these news seem like smoke and mirrors. This makes AI a topic that aluminum manufacturers find difficult to understand and consider its usefulness in alloy design and manufacturing. In this new pursuit of using AI tools to improve manufacturing, it is necessary to separate the ambiguous information presented in AI news and focus on the information about the usefulness and practicality of tools such as machine learning. It is now time for extrusion machines to adopt machine learning to improve efficiency, enhance understanding of the production process, and better utilize the new and existing equipment functions – all of which are aimed at enhancing the competitive advantage of the extrusion industry.