Beautiful Plants For Your Interior

Aluminum alloy profiles are widely used in the construction industry due to their environmental friendliness, stability, ease of processing and decorative properties. Aluminum alloy profiles can be classified into base profiles, anodized profiles, electro-coated profiles, powder-coated profiles, fluorocarbon-coated profiles, through-bar insulation profiles, and injection-molded insulation profiles, etc. Next, Leon LI will introduce the production process of aluminum alloy profiles to everyone.

A:Mold Making

- Mold Design – Utilizing the CAD SOLIDWORKS software to create precise drawings

- Machine processing – Using a lathe, the steel billet for the mold is processed to achieve the desired diameter and thickness. At the machining center, the welding chamber and holes are also machined.

- Heat treatment – Performing heat treatment on the molds in a vacuum quenching furnace to enhance the hardness of the molds.

- Wire cutting – Producing mold hole dimensions through wire cutting processing

- Electrical discharge – Electrical discharge machine cuts out the working section of the mold

- Polishing – After the entire model is completed, the mold is polished to create a smooth working surface, which is necessary for extruding smooth-profiled profiles.

- Inspection – Mold Testing – Nitriding – Strengthen the working band of the mold to increase its strength to 53-54 degrees, making it more durable.

B:Casting

- Loading ingredients into the furnace – In accordance with the specified ratios, prepare raw materials such as aluminum ingots and intermediate alloys, and pour the aluminum ingots into the melting furnace.

- Melting – Using natural gas to burn and melt the aluminum ingots. Stirring to ensure uniform composition and temperature. Raising the temperature of the aluminum liquid to prepare for adjusting the composition and refining.

- Cooperate with Jin – Adjust the proportion of aluminum liquid components according to the alloy requirements

- Precise slag removal – Removing slag and gas from the aluminum liquid to improve the quality of the aluminum liquid.

- Settling – used for precise filtration

- Casting – Continuous casting, producing aluminum rods of various specifications

- Homogenization – The aluminum rods are placed in the homogenization furnace for uniforming their composition, in order to eliminate the residual stress in the ingot, improve processing performance, increase the extrusion speed, and ultimately complete the production of homogenized aluminum rods.

C:Squeezing

- Heating of the aluminum rod – controlled within the range of 410 to 500 degrees

- Compression – According to the principle of “high temperature and low speed, low temperature and high speed”, the profiles are extruded.

- Straightening – Through cold bending correction, the profile is straightened to eliminate defects such as bending and twisting, while avoiding the formation of bumpy surfaces or unevenness.

- Artificial aging – Conducting aging treatment strictly in accordance with the aging process regulations to enhance the strength of the alloy.

- Packaging for storage – For aluminum profiles that do not require further surface treatment, they are packaged for storage after undergoing a series of measurements such as length and strength.

D1:Surface fluorocarbon treatment

Through electrostatic action, apply difluorohexene onto the aluminum alloy and its surface. The resulting color is uniform, resistant to fading and has excellent anti-stain properties.

- One time of mounting – Mount the extruded aluminum alloy component

- Pre-treatment – In the pre-treatment area, the materials are subjected to multiple cleaning procedures in accordance with the regulations, thoroughly removing surface oil stains.

- Chromation – Chromation is carried out in a chromation tank. A fine and stable chromium coating will be formed on the surface. The excellent adsorption ability can enhance the adhesion of the coating.

- Drying – Place the chromed aluminum material in the drying oven.

- Second re-shelfing – Perform local sanding before spraying to ensure the material is smooth and free of dust.

- Paint coating – Two coats and one baking. For this process, “base coat and top coat” coating is required. Three coats and one baking requires “base coat, top coat, and varnish”. Four coats and two bakes need to undergo “base coat, isolation coat, baking, top coat, and varnish”.

- Baking and curing – Packaging and storage

D2:Powder Spraying

It is achieved by applying a powder coating on the aluminum alloy through electrostatic action. The coating has strong adhesion, durability, anti-peeling ability and resistance to ultraviolet rays.

- Shelfing – Place the extruded profiles on the shelves.

- Pre-treatment – After thoroughly cleaning the surface oil stains of the materials in accordance with the procedures, chromium plating is carried out.

- Drying – Place the chromium-coated aluminum material in a furnace for drying

- Spraying – Enter the spraying area for powder spraying

- Curing – Let the powder undergo curing at 200 degrees.

- After drying, remove from the rack – After passing the inspection, pack into the warehouse

D3:Anodize

During the anodizing process of aluminum alloy, an aluminum oxide film will form on the surface through electrolysis. After the anodized aluminum alloy undergoes electrolytic coloring, it can produce various colors.

- Place on – Place on the conductive rack

- Pre-treatment – In the pre-treatment area, the materials are subjected to multiple cleaning procedures in accordance with the regulations, thoroughly removing the oil stains on the material surfaces.

- Anodizing – Placing aluminum profiles in an electrolyte solution and using electrolysis to form an aluminum oxide film on the surface.

- Coloring – The oxidized profiles that require coloring can undergo electrolytic coloring. As time passes, the color gradually deepens from light to dark, allowing for the production of various colors.

- Sealing the hole – Conducting sealing treatment on the oxide film

- Remove from shelf – Aluminum profiles are dried and inspected before being placed on the shelf and packed into storage bins.

D4:Electrophoresis

Based on oxidation, through electrophoresis, a water-soluble acrylic paint film is coated on the oxidation film. The profile will have stronger water resistance, durability, wear resistance, and a smoother and more aesthetically pleasing surface.

- Shelfing – Place the materials on the vertical conductive rack.

- Pre-treatment – In the pre-treatment area, the materials are subjected to multiple cleaning procedures in accordance with the regulations, thoroughly removing the oil stains on the material surfaces.

- Anodizing – Placing aluminum profiles in an electrolyte solution and using electrolysis to form an aluminum oxide film on the surface.

- Coloring – Electrolytic coloring is carried out in the coloring tank.

- Electrophoresis – Place the profiles in the electrophoresis tank and apply the electrophoretic process to form a water-soluble acrylic paint film on the oxide layer.

- Curing – Enter the curing oven and cure to form a film at a temperature of 180 degrees.

- After drying, remove from the rack – After passing the inspection, pack into the warehouse

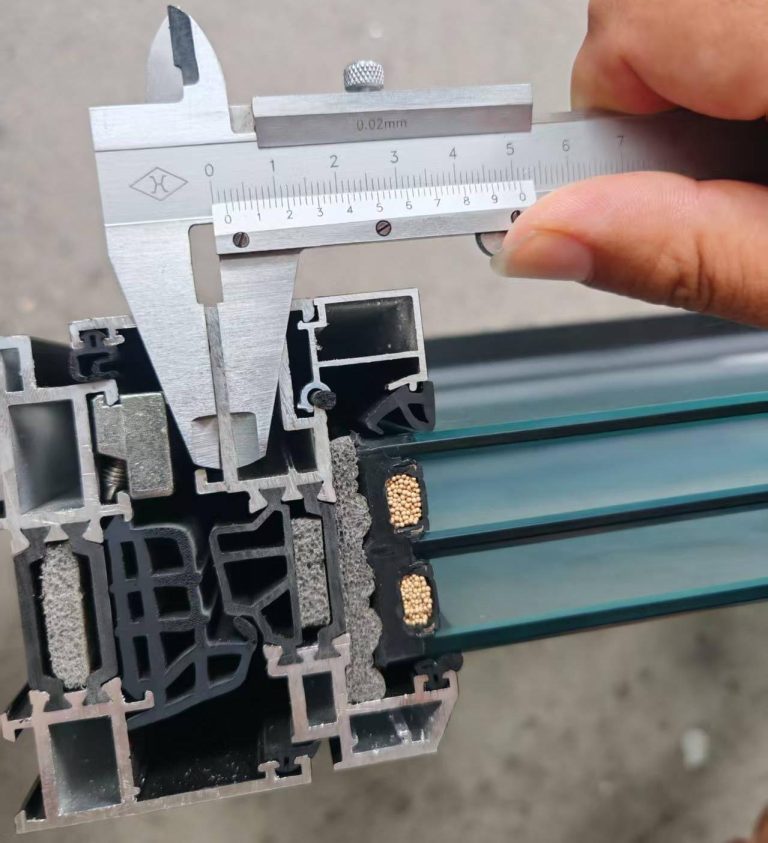

E:Bridge Cutoff

The aluminum profiles that have undergone surface treatment are treated with low thermal conductivity barriers between the inner and outer high thermal conductivity materials. This process enables the product to meet the insulation requirements. There are two types of barrier methods: “strip-through type” and “gluing type”.

strip-through type

- Grinding teeth – Performing grinding teeth treatment on the aluminum profiles to enhance the shear strength of the profiles when combined with the insulation strips.

- Insert a strip – insert a thermal insulation strip between the two types of profiles

- Rolling – Rolling combines two profiles with the insulation strip to form a new type of aluminum profile.

- Inspection – Sampling inspection of shear resistance

- After the inspection is passed, it will be packed and stored in the warehouse.

gluing type

- Sealing the injection cavity – Sealing the injection cavity of the profile

- Power-on preparation – After testing the sample by mixing and stirring the A and B adhesives in the USA Yashon brand, apply the adhesive. The temperature of the profiles and the adhesive tank should be controlled at 20-30 degrees Celsius to ensure that the temperature is not too low, which could cause the adhesive to become brittle.

- Cut bridge – The cut bridge refers to the base material at the connection points on both sides of the profile. By cutting these points, a new type of profile that meets the insulation requirements is formed.

- Inspection – Sampling inspection of shear resistance

- After the inspection is passed, it will be packed and stored in the warehouse.