Beautiful Plants For Your Interior

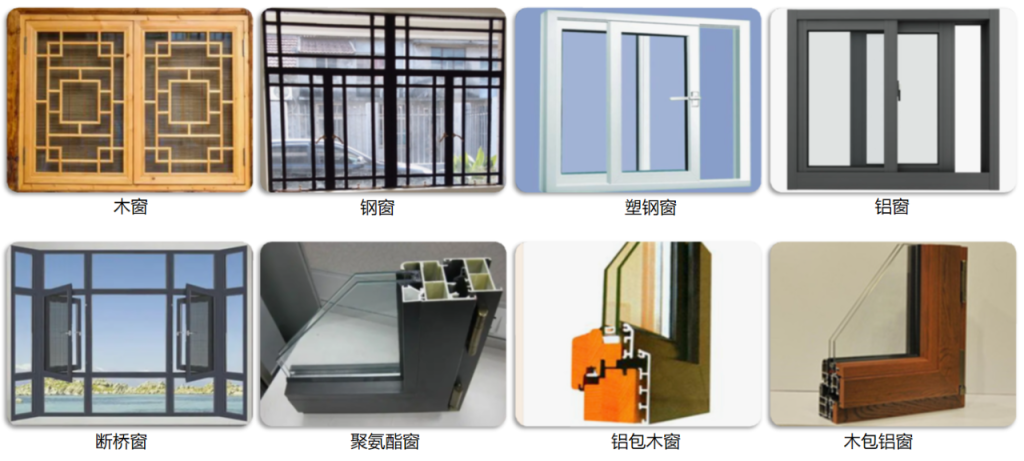

Windows and doors are usually classified by material into: wooden windows, steel windows, plastic-steel windows, aluminum alloy windows, thermal break aluminum alloy windows, polyurethane windows, aluminum-clad wood, and wood-clad aluminum windows, etc.

We will briefly describe the profiles, glass, hardware, complete window processing and installation, tendering considerations, and prices of the most commonly used breakable aluminum alloy windows in five separate articles.

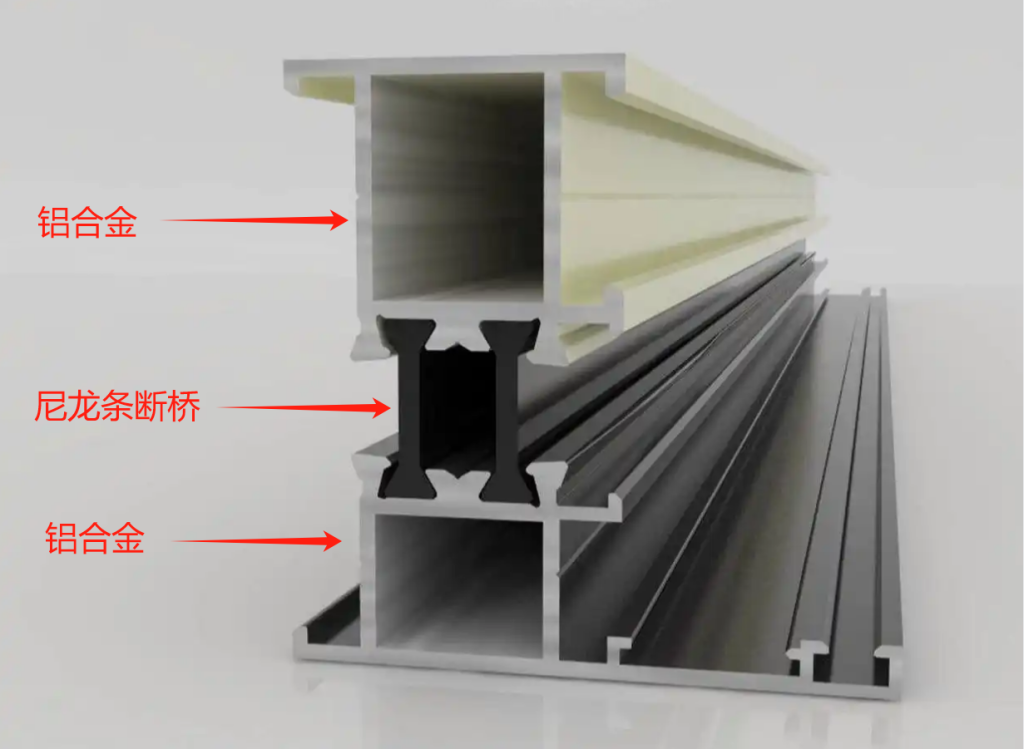

The so-called “broken bridge aluminum profile” literally means that “bridge” refers to the “cold bridge/heat bridge” in materials science, and “broken” means to separate the cold and hot bridges. Aluminum alloy, as a metallic material, has good heat-conducting properties. In summer, when the outside is hot, the aluminum alloy does not insulate. In winter, when the outside is cold, the aluminum alloy does not retain heat. Therefore, by using a material with poor heat conductivity to break the connection in the middle of the aluminum alloy material, it can effectively block the heat transfer and significantly improve the insulation and heat preservation effect.

A、Manufacturing Procedure

Aluminum alloy aluminum rods – heated extrusion – cutting – aging furnace treatment – pre-treatment before spraying – powder spraying / fluorocarbon spraying – threading – film application – packaging.

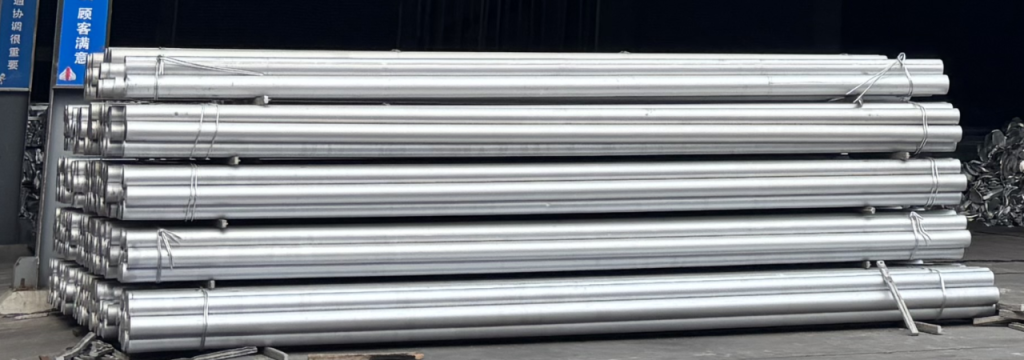

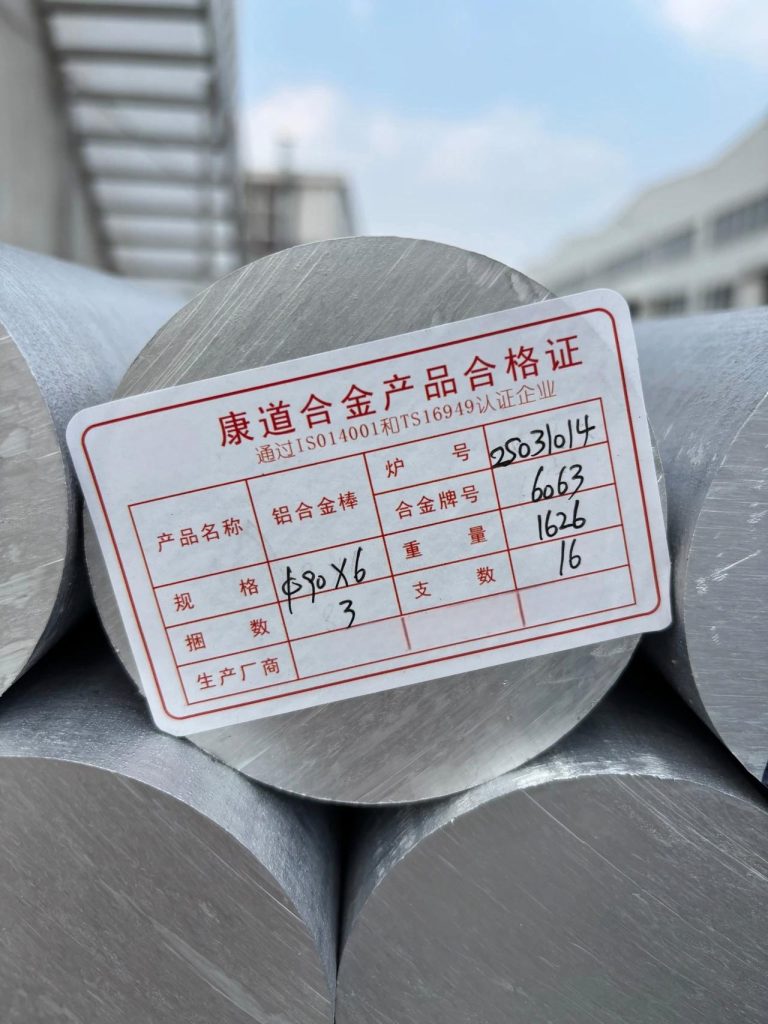

1、Raw material: Aluminum rod

The aluminum ingots must be of grade A00, made of pure aluminum with an aluminum content of 99.7%, and recycled aluminum shall not be used as raw materials. The aluminum rod processing factory melts elements such as aluminum, magnesium and silicon in a certain proportion. The aluminum rod grades vary with different ratios and properties. The commonly used grade for engineering windows is 6063 (The composition of 6063 alloy is generally controlled as: magnesium Mg: 0.45%-0.65%; silicon Si: 0.35%-0.50%; Mg:Si = 1.25-1.30; impurity iron Fe controlled at <0.10%-0.25%; manganese Mn < 0.10%). As we can see, it is about adjusting silicon, magnesium, controlling iron and manganese.

The profile factory directly purchases aluminum rods of alloy according to national standards.

2、Extrusion Forming

The 6-meter-long aluminum rods are cut into fixed lengths, then inserted into the extrusion machine equipped with various types of molds and heated for extrusion molding, much like extruding noodles.

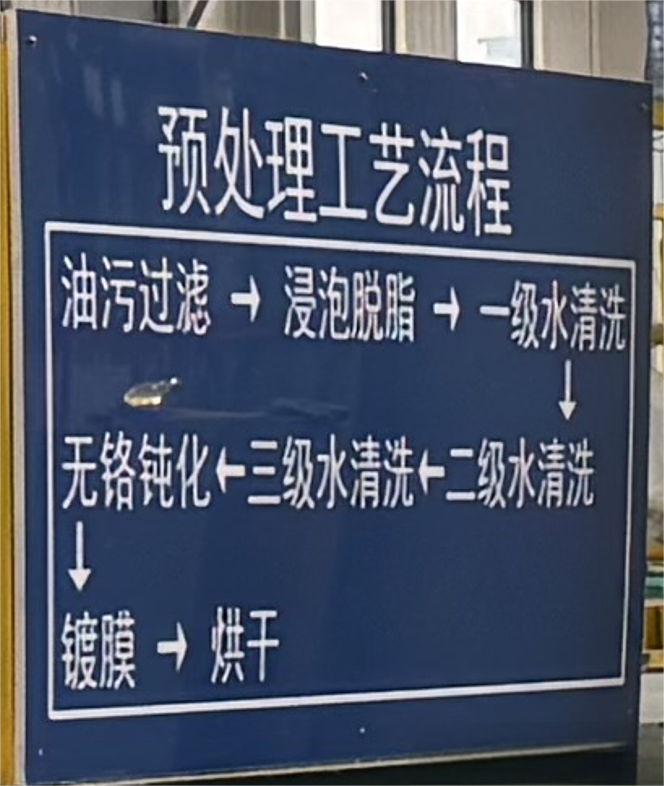

3、Pre-treatment before spraying

The pre-treatment process for profile spraying involves two methods: immersion type and spray type. This picture shows the immersion type. The immersion method results in more thorough reactions and better controllability of quality.

4、Surface treatment (taking electrostatic powder coating as an example)

The raw materials for powder coating can be classified by grade as domestic (such as Aiguo, Jin Goli, Qianjiang, etc.) and imported (such as AkzoNobel, Tiger, PPG, etc.). The thickness is controlled within 40-120 μm. For regular dark brown or common colors, the domestic powder coatings are fully capable.

- Horizontal spraying

- Vertical spraying

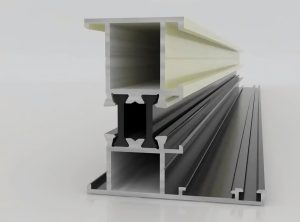

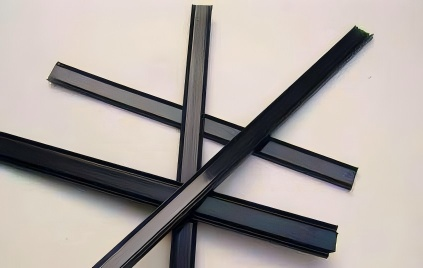

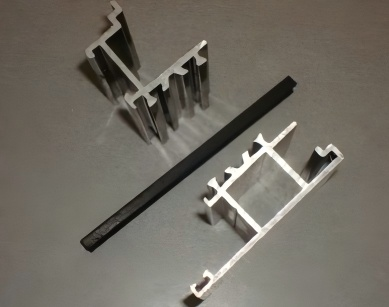

5、Insert the nylon strips

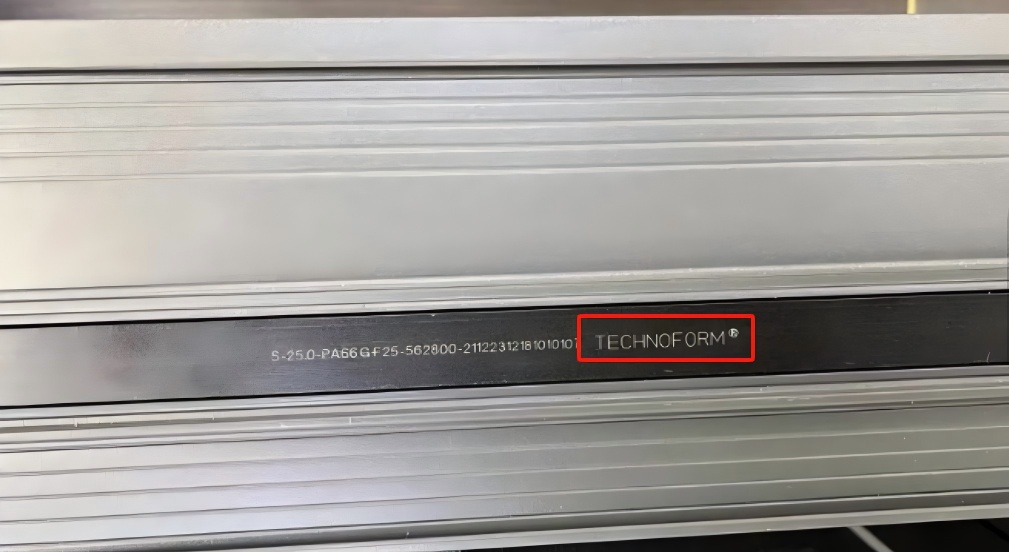

The sprayed aluminum alloy interior material and exterior material should be threaded together using nylon strips. The material must be PA66 nylon strips. Do not use inferior PVC or even recycled materials as a substitute. Be sure to pay attention to this.

The brand and grade of the insulation strips are headed by German Technoform.

The domestically produced Shanghai Yutai and Shandong Baite in China are also fully capable of handling the task.

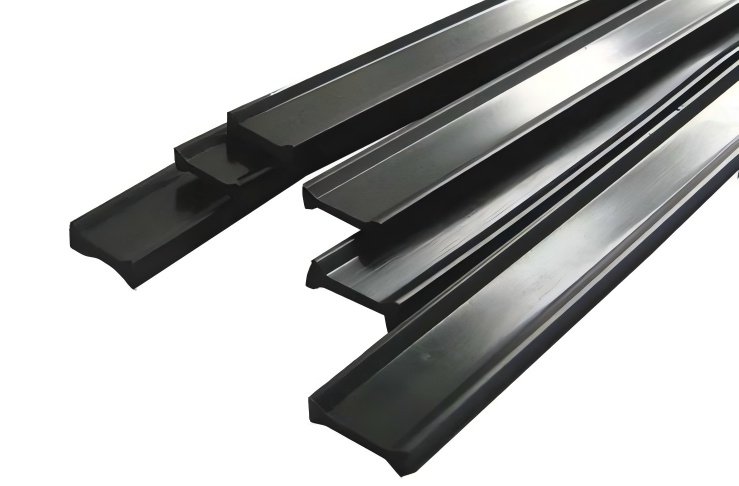

The insulating strips are classified by their cross-sectional shapes into types I, C and T. Taking the simplest type I as an example, the cross-section is as follows:

The aluminum alloy tooth groove can simply hold the two ends of the insulation strip and insert it in. The equipment uses a profile toothed strip insertion machine.

Here, the complete broken bridge aluminum profiles have been produced.

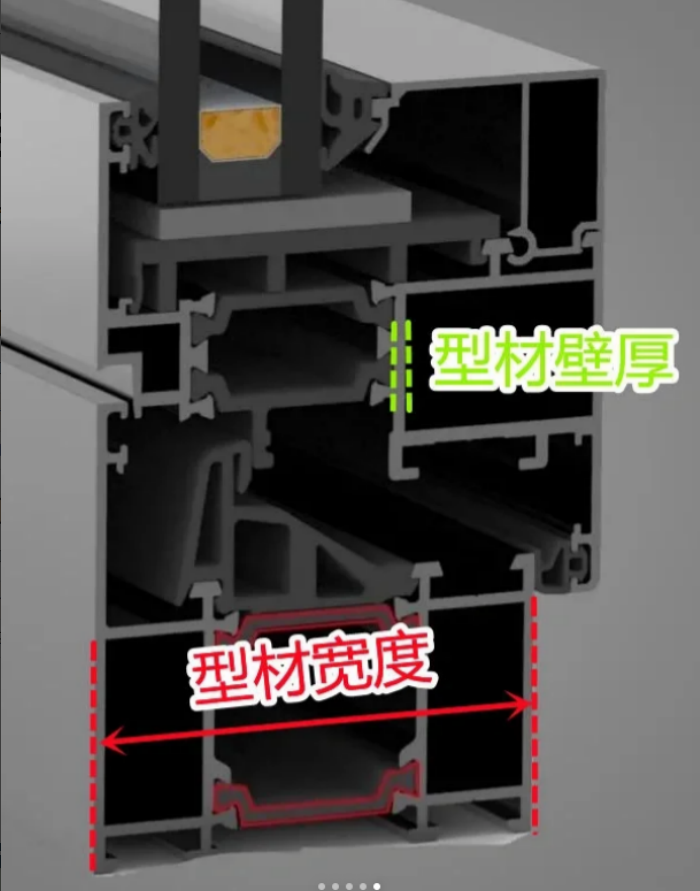

B、Series and wall thickness

1、Series: The 60 series and 65 series that we often hear about refer to the widths of the overall window material profiles, which are 60mm and 65mm respectively. The larger the number, the greater the structural strength and the better the insulation and heat preservation effect. Of course, the cost is also higher.

2、Wall thickness: This refers to the wall thickness of the cavity structure of the profile. The new national standard GB/T 8478-2020 has imposed stricter requirements on the wall thickness of building doors and windows. Specifically, the wall thickness of door materials has been increased from 1.2mm to 2.0mm, and the wall thickness of window materials has been raised from 1.4mm to 1.8mm. The new national standard officially came into effect on February 1, 2021.

Note that the “T” here means “recommendation” and it is not a mandatory standard. Therefore, considering the current sluggish market and the relatively less extreme weather conditions in the northern inland areas, the old national standard will still be largely followed, with a window material thickness of 1.4mm.

C、Price

1、Price composition: The price system of profiles is basically calculated based on the spot price of A00 aluminum ingots in the Yangtze River region plus processing fees (ranging from 4,000 yuan to 6,000 yuan per ton). This depends on the grade of the insulation strips, surface treatment processes, as well as the management costs, profits, and risks of the manufacturers. For example, if the processing fee is 5,000 yuan per ton, and today’s aluminum ingot price is 20,230 yuan per ton, then the finished product price is 25,230 yuan per ton.

Calculation method: The actual purchase price is divided into weighing price and measurement price. The weighing price includes the surface treatment and packaging in the weight (each ton contains 100-120 kg), while the measurement price is calculated based on the theoretical weight of the design cross-section diagram plus the weight of the reinforcing strips. Therefore, the measurement price is 800-1200 yuan per ton higher than the weighing price. Through practical procurement comparison, purchasing based on measurement is more conducive to controlling costs and achieving actual cost reduction and efficiency improvement, reducing excessive packaging waste. When purchasing based on the weighing price, attention should be paid to whether the packaging exceeds the standard; when purchasing based on the measurement price, only the wall thickness needs to be checked.